FIS 1000 – Surface Camera

Surface Inspection FIS-1000®: Precision in Measurement

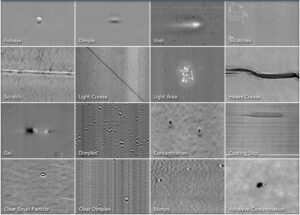

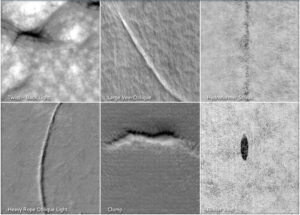

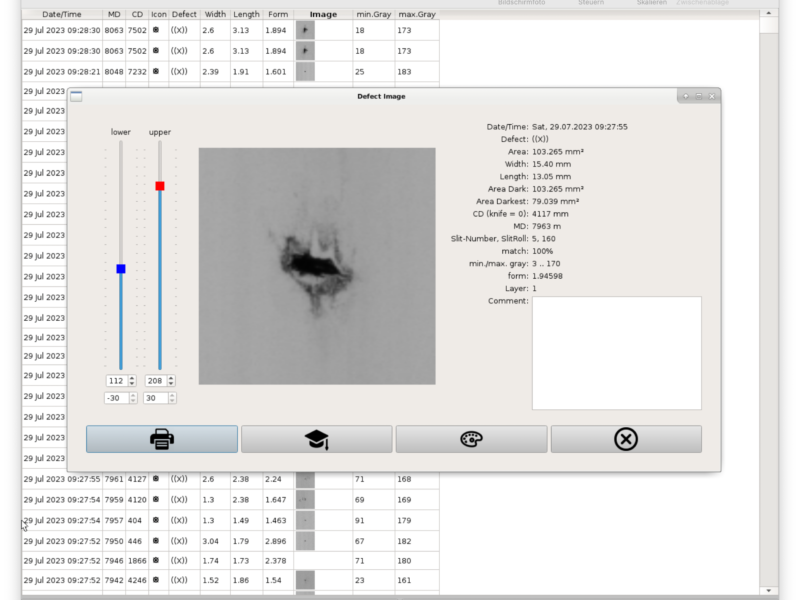

The FIS-1000 is a prime example of precision and efficiency in web inspection. Designed to meet diverse manufacturing needs, this system offers high accuracy, ensuring maximum quality in every production batch. Detect defects such as gels, black spots, holes, insects, oil marks, and many other contaminants with real-time monitoring.

Whether it’s film, biaxial film, or nonwovens and textiles, the FIS-1000 ensures optimal quality and consistency in every frame.

Biaxial Film Inspection: Tailored for biaxial film production monitoring the stretching process.

Nonwoven & Textile Inspection: From fiber distribution to texture consistency, ensure that every textile meets the desired specifications.

Key Features:

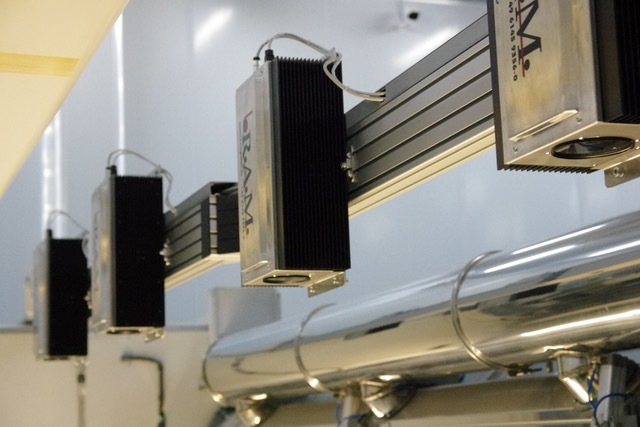

- High-Resolution Imaging by Multi Camera: Starting at 4,096 pixels in CD, with options for 8,192, and up to 16,384 pixels.

- Fast Sampling Rates:Achieve sampling rates from 20,000 to 100,000 lines/sec, allowing high resolution in Machine Direction (MD) even at high production speeds.

- Advanced Calibration: Minimize edge distortion in long lines for accurate imaging.

- Optimized Defect Detection: In conjunction with the CAMEN process control software, generate and process up to 256 thresholds. This ensures only relevant manufacturing defects are recognized, analyzed, and displayed.

Compact & Robust Design: The camera’s compact design ensures optimal modularity. The camera head and processing unit are passively cooled via a side-mounted heat sink, making it suitable for ambient temperatures up to 50°C. Options for air and/or water cooling are available for higher ambient temperatures.

TECHNICAL DATA

Line Camera

| Camera | Pixel | Lines/Second | Frequency |

| RAM-CAM-4k100 | 4.096 | 100.000 | 410MHz |

| RAM-CAM-4k172 | 4.096 | 172.000 | 704MHz |

| RAM-CAM-8k135 | 8.192 | 135.000 | 1,11 GHz |

| RAM-CAM-8k150 | 8.192 | 150.000 | 1,23 GHz |

| RAM-CAM-16k70 | 16.384 | 70.000 | 1,15 GHz |

| RAM-CAM-16k100 | 16.384 | 100.000 | 1,64 GHz |