ITG 600®: Advanced Optical Detection in Foil Production

Step into the forefront of foil inspection with our ITG 600® Rewinder system. This advanced solution is meticulously designed to detect, classify, and record optical faults in the production of both transparent and opaque foils. With the ITG 600®, you’re not just ensuring quality; you’re setting a new industry standard.

Key Features:

- Potential Free Alarm Output: Seamlessly stops the machine upon detecting a flaw, ensuring immediate attention.

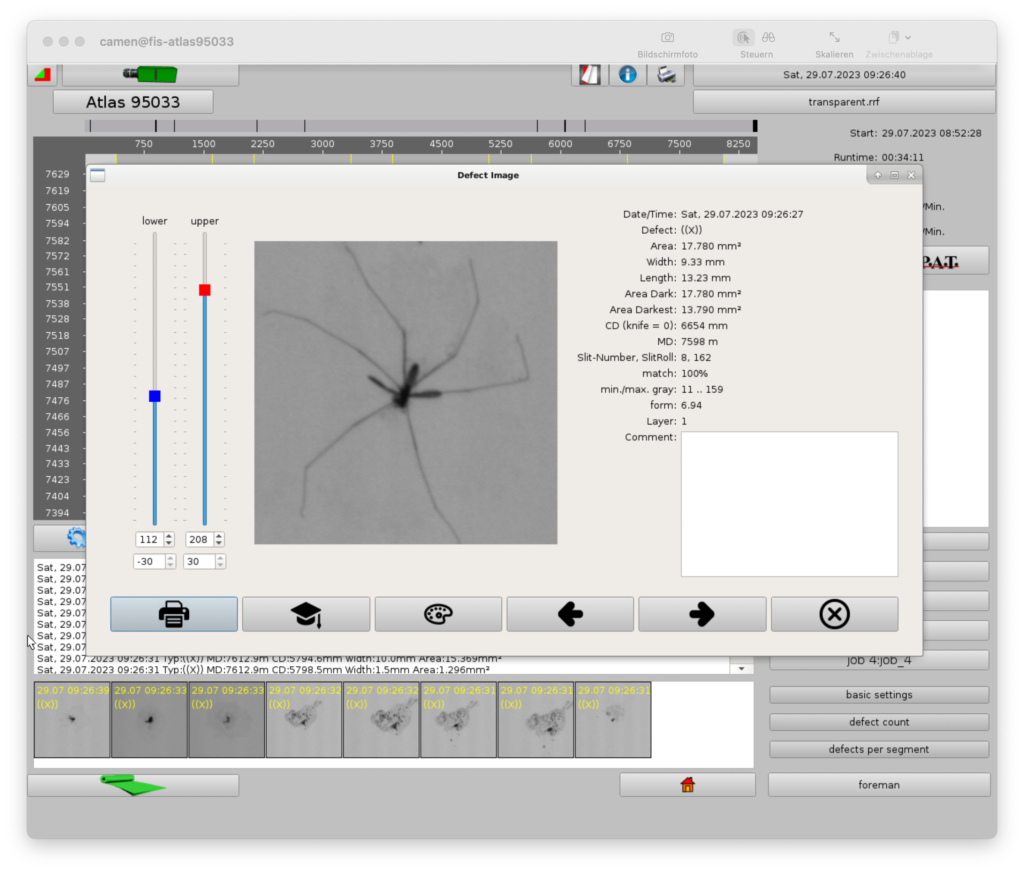

- Automated Defect Classification: Whether it’s specks, gels, burns, fisheyes, impurities, wrinkles, holes, or flies, our system categorizes every defect. This facilitates a detailed post-production analysis using RAM_PAT®.

- Defect Report (MAP): A comprehensive report showcasing defects either graphically or symbolically, complete with roll number, fault quantity (also per m²), and more.

- Recipe Management: Create and manage any number of inspection recipes tailored to specific requirements.

- Automatic Operation Data Upload: Ensures that the inspection system is always updated with the latest operational data.

Connectivity and Integration:

The ITG 600® Rewinder boasts a digital input for roll change or inspection start, an encoder signal, and an output designed to halt the machine when necessary. With such features, the ITG 600® Rewinder stands as a testament to R.A.M. GmbH’s commitment to precision, efficiency, and innovation in foil inspection.

TECHNICAL DATA

ITG 600®

- PC

CPU 16 Gbyte RAM 1 TByte HD SSD for operating system

- Interfaces

1 Input and 1 Output free of potential 1 Input counter for running meters

- Screen

19" LCD-TFT Touch-Screen

- Software

ITG CAMEN 10.xx

- Camera

CMOS Line Camera 4.096 pixel 20.000 scans / sec. 160 MHz.

- System Resolution

CD 150 µm ( width 500mm) MD 170 µm ( at 400 m/Min.)

- Lighting System

LED Lamp 600 mm for 500 mm Inspection width Suitable for reflected light, transmitted light and light/dark field inspection

- Power Supply

230 VAC, 50-60 Hz, 500 W

- Service and Support

230 VAC, 50-60 Hz, 500 W