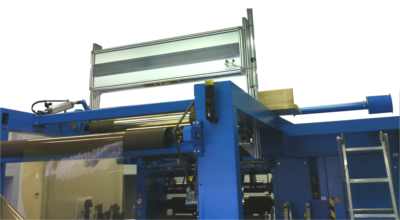

Slitter Rewinder® – ITG700

Precision in Rewinder Inspection

Key Features:

- Dual-Surface Inspection: Monitors both the top and bottom surfaces of opaque films for defects.

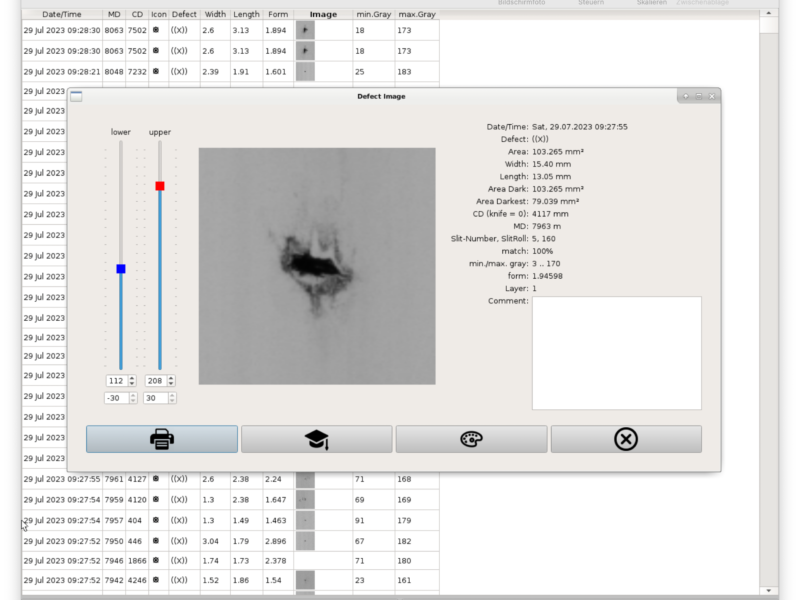

- Automated Defect Classification: Classifies errors into categories such as Specks/Gels, burns, fisheye, impurities, wrinkles, holes, or flies. Additionally, it stores images of these faults for further evaluation.

- Error Report (MAP): Provides a symbolic representation of faults in the roll, including grayscale images. The report details the roll number, total faults, and faults per m², sorted by size class/type. It also displays the location of the error in both machine and transverse directions.

- Recipe Management: Allows for the creation of any number of inspection recipes, ensuring flexibility and adaptability to various manufacturing needs.

- Critical Error Alerts: For significant errors, the system can trigger an alarm lamp, sound a horn, or even stop a winder, ensuring immediate attention to critical issues.

- BDE Data Integration: Seamlessly uploads BDE data to the inspection system for enhanced analysis and monitoring.

- Digital Inputs/Outputs: Equipped with digital inputs for reel change signal, encoder signal, or stop inspection, and digital outputs for controlling alarms during critical error situations.

Applications:

The ITG 700 is engineered for the rigorous demands of modern manufacturing processes. Its advanced features and capabilities make it an indispensable tool for ensuring the highest quality in film/sheet production. Whether you’re looking to enhance quality control, reduce waste, or streamline your manufacturing process, the ITG 700 is the solution you’ve been seeking.

TECHNICAL DATA

ITG 700

- PC

CPU 16 Gbyte RAM 1 TByte HD SSD for operating system

- Interfaces

1 Input and 1 Output with optocoupler 1 Input counter for running meters

- Screen

19" LCD-TFT Touch-Screen

- Software

ITG CAMEN 10.xx

- Camera

CMOS Line Camera 8.192 pixel 40.000 scans / sec. 320 MBit/s

- System Resolution

CD 65 µm ( width 500 mm) MD 170 µm ( at 400 m/Min.)

- Lighting System

LED Lamp 1000, 1500 & 2000 mm for max. 1900 mm Inspection width Suitable for reflected light, transmitted light and light/dark field inspection

- Dimension Cabinet

860 x 860 x 30 mm

- Power Supply

SSH/VPN-Tunnel (DSL necessary) recommended

- Service and Support

230 VAC, 50-60 Hz, 500 W