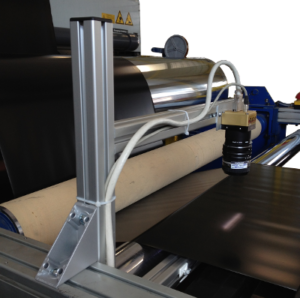

FIS 1000 – Surface Camera

Surface Inspection FIS-1000®: Precision in Measurement The FIS-1000 is a prime example of precision and efficiency in web inspection. Designed to meet diverse manufacturing needs, this system offers high accuracy, ensuring maximum quality in every production batch. Detect defects such as gels, black spots, holes, insects, oil marks, and many other contaminants with real-time monitoring. Whether it’s film, biaxial film, or nonwovens and textiles, the FIS-1000 ensures optimal quality and consistency in every frame. Biaxial Film Inspection: Tailored for biaxial film production monitoring the stretching process. Nonwoven & Textile Inspection: From fiber distribution to texture consistency, ensure that every textile meets the desired specifications. Key Features: High-Resolution Imaging by Multi Camera: Starting at 4,096 pixels in CD, with options for 8,192, and up to 16,384 pixels. Fast