Slitter Rewinder® – ITG700

Precision in Rewinder Inspection Key Features: Dual-Surface Inspection: Monitors both the top and bottom surfaces of opaque films for defects. Automated Defect Classification: Classifies errors into categories such as Specks/Gels, burns, fisheye, impurities, wrinkles, holes, or flies. Additionally, it stores images of these faults for further evaluation. Error Report (MAP):

Read moreFIS 1000 – Surface Camera

Surface Inspection FIS-1000®: Precision in Measurement The FIS-1000 is a prime example of precision and efficiency in web inspection. Designed to meet diverse manufacturing needs, this system offers high accuracy, ensuring maximum quality in every production batch. Detect defects such as gels, black spots, holes, insects, oil marks, and many

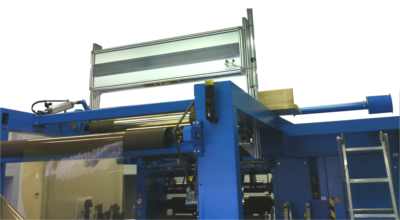

Read moreRewinder – ITG600

ITG 600®: Advanced Optical Detection in Foil Production Step into the forefront of foil inspection with our ITG 600® Rewinder system. This advanced solution is meticulously designed to detect, classify, and record optical faults in the production of both transparent and opaque foils. With the ITG 600®, you're not just

Read more